To allow handling liquids with big size particles and avoid destroying them during pumping process Tapflo developed flap valves as option on the T425 sanitary pump.

Flap valves are designed for trouble-free and reliable operation. Mounted with clamps they provide easy maintenance and cleaning. Maximum size of particles is impressive 48 mm and suction lift is as high as 4.4 meter. Examples of applications are food products with bigger and delicate solids and waste products from slaughterhouses (chicken waste as example).

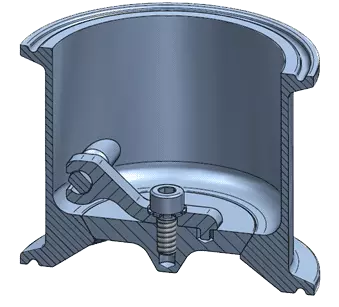

Flap valves made in AISI 316 are mounted in special flap valve cup with clamps between housing and manifold. Pump with flap valves differ from standard pump by valve type, manifold outlet (pos.132), pump housing (pos.11) and pump stand (pos 17).

Flap valves complete can also be implemented on existing standard pumps. The main difference when comparing housing and manifolds in flap valve version is lack of ball stops welded inside, which are reducing max particle size.

Flap valves design is the basis for newer solution of ball cup valves – to mount cup with valve between pump housing and manifolds.

There are two executions available: Standard – Industrial (CTS I) and Hygienic (CTS H):

CTS H with excellent electro polished surfaces, FDA approved seals, high finish and mechanical strength, meet the demands from food and sanitary applications.

CTS I with AISI 316L chemical resistance and mechanical strength is a reliable choice for industrial applications

| CTS-H | CTS-I | |

| USP VI approved materials U.S. Pharmacopeial Convention (USP) class I to VI defines how a plastic or rubber material may be exposed of human tissue. Class VI requires the most stringent testing and such materials may be used for example in implant devices. |

OPTION | |

| EHEDG certified products The EHEDG (European Hygienic Engineering & Design Group) certificate proves that the design is according to the hygienic guidelines. Furthermore certified products are clean ability tested. |

||

| FDA §21 CFR 177 materials FDA (U.S. Food and Drug Administration) §21 CFR 177 lists polymers, e.g. rubber and plastic materials approved for equipment in contact with food products. |

STANDARD | |

| EN 10204 material traceability The EN 10204 norm gives you a checklist and traceability of materials used in the equipment. 2.1 is a general statement of compliance with material specifications, while 3.1 provides specific track records all the way to the steel mill batch (normally only on metals in contact with the product). |

OPTION | OPTION |

| EC 1935/2004 regulation This EU regulation applies to all food contact materials, e.g. metals, plastics and rubber materials. It requires that these materials are safe, are labeled with the glass-and-fork symbol, are traceable throughout the production chain (according to above EN 10204) and that they are produced according to good manufacturing practice (GMP). |

STANDARD | |

| CE conformance A product classified as machinery that carries the CE mark fulfill the essential health and safety requirements of the EC Machinery Directive 2006/42/EEC. |

STANDARD | STANDARD |

| ATEX Directive 94/9/EC Equipment intended and approved for safe operation in potentially explosive atmospheres. The equipment is divided in main groups, categories, apparatus groups and temperature classes to define its suitability in the actual zone. |

OPTION | OPTION |

text

Par Tapflo. Tapflo grupa ir neatkarīgs, ģimenes īpašumā esošs Eiropas ražotājs un globāls membrānu sūkņu, centrbēdzes sūkņu un citu rūpniecisko procesu iekārtu piegādātājs. Tapflo savas pārstāvniecības ir 30 valstīs un neatkarīgi izplatītāji vairāk nekā 45 valstīs.